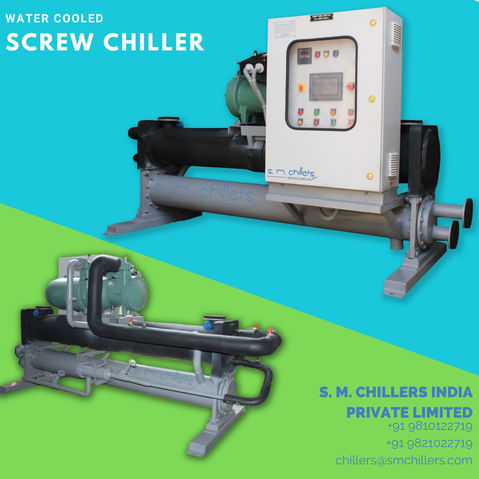

SM Chillers India, a renowned Industrial Chiller manufacturer, specializes in producing high-quality screw chillers that cater to a diverse range of industrial and commercial cooling needs. With a commitment to innovation, energy efficiency, and customer satisfaction, SM Chillers has earned a strong reputation in the industry. In this comprehensive description, we'll explore the working principle and features of SM Chillers' screw chillers.

Working Principle of Screw Chillers:

Screw chillers operate on a thermodynamic cycle that involves the compression, condensation, expansion, and evaporation of a refrigerant. The core components include the twin-screw compressor, evaporator, condenser, expansion valve, and a refrigerant loop.

-

Compression: The process begins with the compressor. SM Chillers' screw chillers use twin-screw compressors, which are renowned for their reliability and efficiency. The compressor's role is to draw in low-pressure, low-temperature refrigerant vapor and compress it, raising its temperature and pressure significantly.

-

Condensation: The high-pressure, high-temperature refrigerant vapor then moves to the condenser, where it releases heat to the surrounding air or a cooling medium (like water). This causes the refrigerant to condense into a high-pressure liquid.

-

Expansion: After condensation, the high-pressure liquid refrigerant passes through an expansion valve, where it undergoes a sudden reduction in pressure. This expansion results in a drop in temperature, causing the refrigerant to evaporate and turn into a low-pressure, low-temperature gas.

-

Evaporation: The low-pressure refrigerant gas is now directed to the evaporator, which is usually located in the space or area that needs cooling. In the evaporator, the refrigerant absorbs heat from the surroundings (e.g., a building or industrial process), causing it to evaporate and return to the compressor as a low-pressure vapor. This cycle repeats continuously to maintain the desired cooling effect.

Key Features of SM Chillers' Screw Chillers:

-

Advanced Twin-Screw Compressors: SM Chillers' screw chillers are equipped with twin-screw compressors known for their efficiency, reliability, and smooth operation. These compressors provide consistent cooling performance and are ideal for demanding applications.

-

Energy Efficiency: SM Chillers places a strong emphasis on energy efficiency. Their screw chillers incorporate Variable Frequency Drives (VFDs) that adjust the compressor speed based on the cooling load, reducing energy consumption and operating costs.

-

Wide Range of Cooling Capacities: SM Chillers offers a comprehensive range of screw chillers to accommodate various cooling needs, from small-scale applications to large industrial processes. These chillers are versatile and suitable for industries such as manufacturing, data centers, and commercial spaces.

-

Environmentally Friendly Refrigerants: SM Chillers is committed to environmental responsibility. Their screw chillers use eco-friendly refrigerants with low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP), aligning with global sustainability initiatives.

-

User-Friendly Controls: SM Chillers' screw chillers are equipped with intuitive control systems that allow users to monitor and manage the chiller's operation efficiently. These controls enable precise temperature regulation and system optimization.

SM Chillers India's screw chillers are the epitome of advanced cooling technology, designed to provide reliable and efficient cooling solutions for a wide range of applications. With their commitment to innovation, energy efficiency, and environmental sustainability, SM Chillers continues to set the industry standard for screw chiller excellence.

Screw Chiller Manufacturers in India

Cooling capacity

The screw chillers manufactured by SM Chillers India Private Limited are designed to provide high cooling capacities. They offer chillers with cooling capacities ranging from 30 TR to 500 TR, which can be customized based on customer requirements.

EFFICIENCY

SM Chillers India Private Limited's screw chillers are designed to be energy-efficient. They are equipped with high-quality compressors that ensure optimal performance and reduce energy consumption. The company also offers chillers with variable frequency drives that adjust the cooling capacity based on the load, resulting in even higher energy savings.

DURABILITY

SM Chillers India Private Limited uses high-quality components to ensure the durability of their chillers. Their chillers are designed to withstand extreme temperatures and harsh environments, making them ideal for use in industries such as food processing and pharmaceutical manufacturing.

CUSTOMISABLE

The chillers manufactured by SM Chillers India Private Limited are highly customizable. The company can design and manufacture chillers according to the specific requirements of their customers.

COMPACT DESIGN

The screw chillers manufactured by SM Chillers India Private Limited are designed to be compact. This means they can be installed in tight spaces without compromising performance.

LOW MAINTENANCE

The chillers manufactured by SM Chillers India Private Limited require low maintenance. They are designed to be durable and reliable, and require minimal maintenance to keep them running smoothly.

WIDE RANGE OF APPLICATIONS

The screw chillers by SM Chillers India Private Limited are suitable for a wide range of applications. They can be used in industries such as food processing, construction, and plastics.

ADVANCED CONTROLS

The chillers manufactured by SM Chillers India Private Limited come with advanced controls. This allows for precise temperature control and helps to optimize energy consumption.